Wind energy, being one of the most important renewable energy sources, and wind turbines, which are necessary for producing wind energy, are very important in today's environmentally aware world. Below we outline detailed information about generators, with many power options right up to 7 MW, as well as one of the most important components of wind turbines and motors that is used in place of generators in individually made wind turbines.

Permanent Magnet DC motors are the most important components that can be used in place of generators. The magnetic fields produced as a result of the spiral movement of the magnet within the component is that which produces electricity.

Why Use a Motor to Generate Electricity?

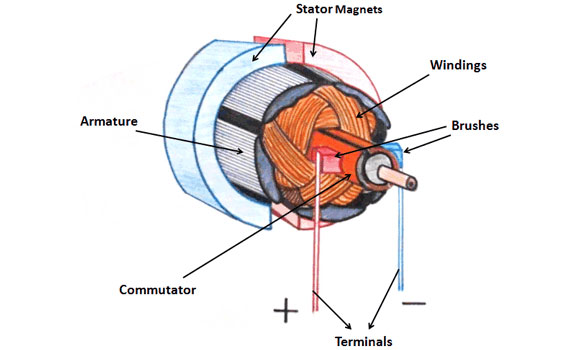

The most important reason is that it is cheaper than electric generators and it also contains many components we utilize in our daily lives. A motor is a device that converts electric energy into mechanical energy when electrified via its outputs; however, permanent Magnet DC motors can also have some adverse affects. The magnetic field created by the magnets causes a current to flow through a coil. You can see how electricity is produced in the below picture.

Permanent Magnet DC Motor Types for Generating Electricity

Permanent magnet DC motors are divided into two groups. The first is the permanent outer magnet and moving coil, while the second is the permanent coil and moving magnet.

Brushed DC Motor: These motors contain a permanent magnet and a moving coil within the magnet. The required electricity is produced by conveying the energy produced by the revolving brushes. Brushed DC motors are not the preferred method for producing electricity because the coil's, being in continuous motion, can have the following affects on the brushes:

a.) Degradation,

b.) Difficulty in producing electricity because of the brushes

You can see a brushed DC motor in the below;

Brushless DC Motor: These motors are the preferred choice of motors for producing electricity. Thanks to the moving magnet unit in the permanent coil, it easily produces electricity. Producing high efficiency and continuous electricity are the main features of brushless DC motors.

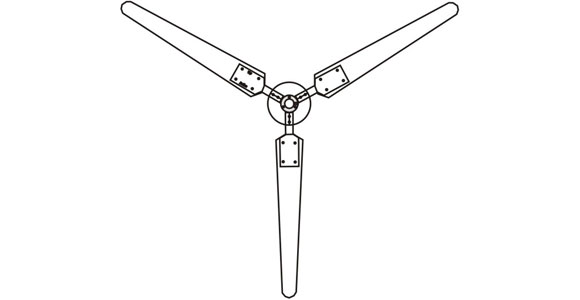

It is one of the most easily found motor types for those that want to build a wind generator at home. Wind energy is converted into rotation energy with the help of the blades installed on the edges of the motor and then converted into electricity with the help of the motor.

You can see images of the brushless DC motor below;

Working Principle of Brushless DC Motor

As mentioned above a magnet with two poles is rotated around a permanent coil to produce electricity.

Detailed information is given in the below picture;

Best Motor Types to Build Wind Energy Turbine

Some types of motors are more efficient than others. With the same wind speed one can produce 10W whereas the other produces 40W.

1.) Treadmill Motors: These motors are both robust and efficient. This is our top recommendation for motors for producing electric energy. You can find them easily online or in stores selling second hand products. They cost between $20 and $250. Because of its values in relation to output current and output voltage, it can easily be used as wind turbine generator.

2.) Stepper Motors: Although highly efficient, stepper motors have a lower output voltage and current than treadmill motors. It can be used in wind systems that have a lower power output.

3.) Standard Permanent Magnet Motor: These are for people who want produce electricity out of wind energy. They are cheaper than treadmill motors but some have higher HP levels. Sold for $20 - $1500, standard permanent magnet motors are our second choice for wind energy systems.

AC Motors to Generate Electricity

The most important component for producing electricity with motors is the magnet. There are no magnets in AC motors and the energy needed for the motor is provided by AC voltage.

How to Choose the Right DC Motor?

The details you need to pay attention to before you choose a DC motor for producing electricity are:

Power Selection: It is hard to rotate motors with high power capacity, therefore the wind turbine blades should be chosen in accordance to the motor power. If the area you set up the wind turbine does not have enough wind, it would be wise to use motors with 1 – 3 HP power. If the wind speed is regularly 15 Mph and over, you should use 10 HP motors.

Power Requirement: It would be better if you used a turbine that is in accordance with the need of energy of that area. The selection of motor is also important; it should be consistent with the size of the turbine. For example, if you need 2000 Whrs of power, you will need to install a 2500 Whrs system.

Blade Design: Along with the wind speed, the design of blades, which divert wind energy into rotation energy, is important. For example, the rotating speed of a 3-blade system and a 6-blade system differ from each other. Because of this, the motor you choose to use has to be in harmony with the blade design.

Motor Power: If you need 1500W energy and you use a motor that produces less than that, you could damage your motor. You should, therefore, use motors that are 30% stronger.

Wind Turbine Motor Basic Calculations

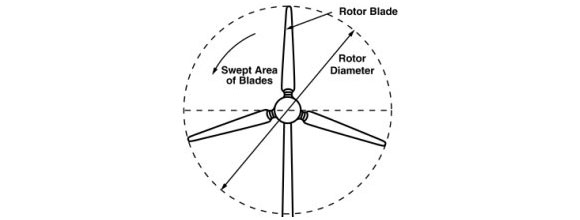

The motor you choose should be built according to variables such as wind speed, blade design, blade number, and rotor diameter. These variables in detail:

Wind Speed: Is the amount of wind passing through a specific area. It is defined by variables such as mph (mile per hour), kph (kilometer per hour), and m/s (meters/second). The wind turbines used today start to rotate with 5 mph wind speed and work efficiently between 25 and 60 mph.

Blade Design: Although wind speed is the most important factor for rotation, the blades are the main components for converting wind energy into mechanical rotation energy. For this reason the blade design is very important for efficiency.

Number of Blades: The number of blades influences the efficiency of the wind turbine. 2, 3, 5 blade wind turbines are frequently used. It is known that the more blades used, the more reliable and safe the wind turbine is. They work more silently and are more efficient. The cost is an adverse factor though.

Blade Efficiency: Is related to the blade design part we mentioned above. The more efficient the blades, the more energy produced.

Rotor Diameter: Meaning the turning diameter of the blades. More robust and big sized motors can be used in wind turbines with a high turning diameter.

TSR (tip speed ratio): If the wind turbines rotate too slowly they lose much of the wind passing over them, and if they rotate too fast it is as though they act as a wall, meaning degradation occur. For this reason, optimum tip speed ratio is very important for efficiency. Some TSR ratios are;

- 2 Blades: 9 – 10

- 3 Blades: 6 – 8

- 5 Blades: 4- 6

Basic Calculations: The average wind speed in your region as well as maximum wind speed must be taken into consideration before building a wind turbine. Suggested figures are:

Average Wind Speed = 25 Mph = 11 m/s

Max Wind Speed = 70 Mph = 31.4 m/s

If the region where you will build a wind turbine has a value of wind speed between the values above, you should arrange the variables like blade size and number. If you want to have 2500 W/hours, the blade length should be 1 – 1.5 meter (3 – 5 feet). The designs with 3 blades can provide 35% - 40% efficiency so we suggest 3 blade designs.

A motor which can generate 2500W power should have;

- 100A output current,

- 25V output voltage,

Or;

- 20A output current

- 125V output voltage.

For this motor to produce maximum power, it should rotate close to the maximum RPM it is intended for. For example, think that a 2500W motor’s RPM value is 1200. To acquire 2500w power in the outputs of the motor we need 1200 rpm (revolutions per minute). The lower the rpm speed, the less the output power.

Basic Power Formula;

Blade length, l = x meter

Wind speed, v = x m/sec

Air density, ρ = 1.25kg/m3

Efficient, Cp = average 0.3 – 0.4

Ptotal=0.5 (x) ρ (x) 3.14 (x) I2 (x) v3 (x) Cp

Examples

We have shown the calculations above but to make them a bit clearer there are some more examples below.

1.) Average wind speed: 35 Mph, Average Power Requirements 4500W, Blade Length =?

V = 35 Mph = 15.7 m/s

Air density, ρ = 1.25kg/m3

Efficient = 0.35

I2 = Ptotal/ (0,5*1,25*3,14*15,7*15,7*15,7*0,35)

I2= 4500/2658

I = 1.3 meter

The blade size should at least be 1.3 meters.

2.) Max RPM = 1200, Vout = 24V, Iout = 100A, Power Requirements = 1000W, Motor Speed =?

Total Motor Power = 24 * 100 = 2400 W

1200 RPM = 2400W

Each Watt = 2400/1200 = 2RPM

1000 = 2 * X

X= 500 RPM

Frequently Asked Questions

Q: What are the differences between the Permanent Magnet DC Motor and Alternator?

A: The Permanent Magnet DC Motor is used to convert electric energy into rotation energy and vice versa. The main purpose of alternators is to produce electricity and they have more production efficiency.

Q: Which is the best DC motor for electricity production?

A: Motors with a lower RPM value and high output voltage might be more efficient.

Q: What are the things that I should take into consideration when I purchase a motor?

A: The standard wind speed is 10–30 Mph, so the motor you will buy should have low RPM values. The blades connected to the motor can produce 400 – 600 RPM speed for a standard wind. For this reason a motor with a maximum 1000 RPM works inefficiently.

Q: How much voltage is required for a 12V battery?

A: To charge a standard 12V battery, 14-16V volts are needed. Make your calculations according to these values.

Q: Can you give details of a good motor?

A: Power = 1 HP, Max 300 RPM, 30 VDC, rpm/volt ratio = 10, 30A Current

Q: What brand and modal of motor would you suggest?

A: Ametek 080987K7 30VDC

Is a charge controller required for batteries?

Not reuquired but this part is important for your battery life.

sir we are doing our final year project in wind and solar power generation . So i want permanent magnet dc motor with 500rpm,80-150volts, 17-20ampere. so please reply me quickly

I suggest you;

– CDP3604 Baldor SCR Drive Permanent Magnet DC Motor:

Voltage: 180V

Amper: 14A

I am looking for a ametek 080987k7 30 vdc pm motor.

Hi,

Contact AMETEK Technical and Industrial Products.

AMETEK 30 VDC – AMETEK 72 VDC-AMETEK 12 VDC , all are available on EBAY.IN .kindly advice which one is good for wind turbine

How much wind speed will be required to run a 12V dc motor?

12×3 = 36V battery bank is good for your systems. Also you need a charge controller for this system not a gear..

How much 24 volt dc motor permanent magnet generate electricity?

Its about motor speed. The motor has 1000 RPM value and motors speed is 1000RPM the output will be 24V.

I just picked up a 1hp treadmill motor today. I put my drill on it at about 400rpm and it produced about 12.6 volts. When I put it up to about 1400 rpms it bumped up the volts to about 42-44. A little lost here in trying to figure out how long to make the blades using 3″ pvc. Average wind speed is about 15mph. Basically want to make this motor be able to charge a 12v battery or multiple batteries… Is it possible or do I need to gear this motor (larger pulley with a belt)?

Hi Scott

12×3 = 36V battery bank is good for your systems. Also you need a charge controller for this system not a gear.

Hi Scott, I think if you start off using 3 x1.5 m length blades, you can judge approx what voltage you would get. Basically the closer you get to plate RPM indicated on the motor, the closer you will get to the voltage indicated on the motor. My thoughts are if you try and place pulleys on, it will create a lot more drag which will require larger blades.

Have made a vertical wind mill from 2 bicycle wheels and pvc slats from blinds. This will be at fence level. More than one aligned in fence formation. Now with 20” wheel spinning at 60 rpm could I put a pulley on D.C. Motors of each with a ratio of 10 to 1. Putting a diode at the positive feed of each independent power source and send it to a Charge Controller for a bank of 4 {12V} Deep Cycle batteries.

For low rpm in breezes would a capacitor be used to build charge to 12 V before pulse discharge? If so what capacitor would serve this scenario or perhaps 3 in parallel would be more advantageous? “OR” none? One more thing if I place 6V batteries in series to provide 12 volts, can I then charge that series at 12V?

I need to find a small generator that will charge a 12v battery or multiple at wind speeds 60 mph. i have a constant wind that can be controled at that speed for 5- 8 hrs a day. Also what would be the shortest blade langth that i could use I am hoping to be able to use a design simular to a squral cage fan. Thank you for all the help you can give.

Can i get the winding details of 1000watts,12volts (or) 24 volts, 300 RPM DC generator , Gauge of copper wire, no of turns,Plase guide me the calculation formulas for these details.Pl help me.

i have a permanent magnet dc motor with 14v, 360rpm., i want to construct a domestic wind turbine to produce 80watts power. is the motor which i selected will be feasible???

I have a 24V 120W dc pm motor and I would to use it as generator to produce a 22 W of power using a hydro turbine. So what should I do regarding the connection from the turbine to the motor? thanks

Hi, I’m working on a wind generator that will be storing power to a deep cycle battery. If I were to use an inverter hooked to the battery, when the voltage of the battery dropped past it’s limit (which causes the inverter to switch off), I would presume if I were to use a 12V solar controller, it’d safely recharge the battery back to its 12v limit and I can reset the inverter and use it again?

I have a treadmill motor that is rated 90 volts DC, with 15 running amps, at 4800 rpm. If my math is right, this little guy can pump out 1350 watts correct? But if I am not tapping power directly from the motor itself, and drawing power from the battery and say I used a 2500 watt inverter at full load, would the motor still overheat and blow? Or would all the draw be put on the battery and the inverter would be a default protection by popping the breaker once the battery’s voltage drops to its “popping point”?

Thanks in advance.

Sir, averge wind speed is 8-10 mph, I want to make a 24V battery system for 2000W. can you please suggent DC motor specs.

2. I would connect it with 24V solar system (Hybrid)as well.

Thanks

hello scot? pls i wanted 2 build a brushless dc magnetic motor that can produce about 24V dc and 100-150A, cuz i cant afford the price at wich the wind turbine is sold in ma country.

i dont know if u can give some info on how 2 go about it. GOD bless u as u reply.

I have access to lots of industrial motors and such can you recommend any good motors for 5 kw output turbine?

i have 2 hp, 110v DC, 2800 rpm treadmill motor. Roated that motor by using belt 1440 rpm 1hp ac motor . it produce 110 ac volt but when i connect 110v to 220v transformer on that DC motor speed decries. what is the problem?

What I have trouble understanding is this:

(This is just an example it will not reflect reality)

Lets say I have a motor producing 130 volts at 15 amps.

I use it to charge my 450 battery bank.

I use 225 amp/hour a day.

225 amphr divided by 15 amp=15

Does this mean my generator has to run 15 hours(assuming its giving me full 15 amps an hour)to reacharge my battery bank?!

What is your battery bank voltage?

Hi all. Can anyone plz suggest if i can run perm maganetic generator through an exyernal motor instead of wind blades? Please mail me

sir,

i am doing a mini project in textile mill where i already have 15 m/s air velocity. I want to utilize it for generating electricity. which alternator or pmdc motor i should prefer to get good power at low cost? please note that i have to attach that alternator or pmdc motor to exahust fan of overall dia 0.8 metre.

Hi sir , I m planning for final yr project as electricity production by wind induced across train.

The avrg speed of train is 55 kmph and will vary 80-100 kmph (mumbai local railway). so what kind of dc motor should I use for my project so as to get best output.

Plz suggest me the dc motor with all its specifications like its max o/p in dc volt for mentioned speed. how much rpm will it suffers at that wind speed. And how much power will it generate. plz note that the blades we r using are not more than 50cm in diameter.

Thank you for your attention.

Is it possible to use this motor on vertical wind turbines?

I’m doing my group project on wind turbine (model) can anyone help me in selecting a motor for generating 5 to 10W of power and blade length should be opted for wind speed of 10-15m/h.

plz giv me reply…..

Hi,

40 vdc ametex motor. Thats safe for 2 12v battery’s connected right? Setting up my system right now and wanted to make sure. i have a solar/ wind charge controller.

Hi,

is the Ametek 080987K7 30VDC a brushless motor? Can I also get the working principle of the motor.

I want to make a permanent magnet DC motor by myself. I want to know the formula of “the magnet power and copper cable to DC Motor power”. That means, if I want 2kw power, how powerful magnet and how much copper cable and how much RPM I require. Can you help me or refer me to any website?

I have a p.m. d.c. motor c3350b3006.18.0 amps.HP 2.25.what size wiring do I use from the motor to the power controler to the batteries.How do I find out how many rpms. it takes for this motor to start charging the batteries.Also how many batteries will I need to rum my house off the grid.I need max. 5000w. But very rear that I use that much at one time.Thank you for for some input.

Hi, I am looking to build a vertical wind turbine to power a 12v dc immersion heating element in a small water tank. I plan to connect the turbine to a 12v wet battery to regulate as the wind speed will fluctuate. Currently getting 9m/s wind speed on site. Was thinking of car alternator, but after reading the above, should I go for a brushless motor with 12v rated around 200rpm? Or would a higher volt or lower rpm rating be better?

Any help or reference at all would be appreciated.

Thanks.

sir.. i want to make a 2kw wind turbine using dc machine.. im using a 24v dc machine. what happens when the prime mover speed increases.. my friends are saying that if speed increases voltage also increases and there is a chance of burning of winding.. please tell me .. what will be the peak voltage it can with stand ( 24v dc machine).. it would be great if u explain me by taking an example of a motor model.. thanks in advance

What size should the copper be to make a 2000rpm DC Motor

Hi, I am building a wind turbine using a electric wheel chair motor. I was told these were a good fit for wind turbines because of the low rpms required.

I found one which has Motor 24V and Brake 12V written on the side of it. I can’t get the voltage to go above 12V by testing with a drill. I got a really high current of roughly 10A.

Would this be suitable for wind turbine with a charge controller added?

sir, we need a 24 volts dc motor genenerator, and we need at least 200watts output power.. we only have 200 to 300 rpm … we need it this week so i hope you have a quick response.. thank you…

I have a 180v treadmill motor running at 3600 rpm. i have geared it for vertical wind generator. im stuck at what size charge controller to use for it. any suggestions would be awesome. thanks in advance.

i want to generate 50volts and 60amp current. so which type of generater is need for it? i want to generete it by wind or mechenical input also.

i just purchased a Ametek 40v dc motor what’s the lengths of blades will I need to get

Sir,

My wind speed was 15 m/s but the wind was came from my Exhaust fan. If it is possible to generate

power using DC Permanent magnet motor.

If Yes, It can generate how much Voltage,Power.

Pls give idea sir………..

sir i have here my permanent magnet DC motor but i dont know the specification of it. it is a product of Jena,,please help me know the specification..i google it but i cant find the specs

my science club and i are planning on building a flying car with 4 sets of blades.

how many blades do you recommend for a motor of power 1500W and if so, what would be the rpm of these blades?

also, does the number of blades alter the rpm of each blade given that the power of 1500W remains the same?

Thank you

please tell me what type of motor can i use for my wind turbine nd where can i get it i ve used 3blades made of pvc pipe (3-5)feet

Hello ,

I am trying to find a DC PMG for a low-wind-speed vertical axis wind turbine around 10 kw can you please recommend a good manufacturer ?

Best regards

I’m trying to build a light, portable VAWT, I need help with a small DC motor that can produce about 10W of electricity. I will be using this to charge small batteries (AA, AAA, etc..) any ideas?

hi, planning to build a 1kw VAWT, kindly advice BOM that required to build it,

I need to find a dc motor that can produce AC, for 1kw, 12/240volts at 250rpm up wards. High speed permanent magnetic generator. I would like to find a Australian manufacturer if possible. I want to buy 100 units at a time. For the purpose of using this within my design concept.

i want to produce approx 1400 rpm from a wind mill

please tell me what blade length should be used?

and what should be the wind speed?

Sir, we are making low head hydro turbine for 100 watt power generation. So plz suggest dc motors for 100 watt power generation 24 volt.

We are designing axial flow hydro turbine for 0.2 – 2 meter/sec of inlet water velocity.

there is probability of 500-1000 rpm than how much power will produce

HI!

Great blog. I have a 1.5 HP pacific scientific DC perm Magnet motor 90 volts 13.3 amps. I am spinning it with serpentine belt and a bicycle. It spins very well and produces 24 volts when not attached to my battery. When I attach it to the battery it becomes very hard to pedal and I cannot get the voltage/amperage that would make this practical. Why is there such a big resistance once attached to battery? I have a diode on positive cable from motor flowing to battery and a diode on negative cable from battery flowing to motor. The negative diode is unnecessary. Without positive diode the motor would spin and power bike.

lets say i have a permanent generator and it say that 2500 rpm will create 120v, how many rpm will the blades need to be to supply enough energy

How can I get that PMG for my generation

Hello, i have 48Vdc set of batt 4×100…what size of VWm i need?

tell me how to recharge my 4×12 volt =48v batteries without electricity

What should be the diameter of the blades in magnetic levitated vertical axis wind turbine with permanent magnet of size 50mm-12.5mm-and thickness 10mm

Sir kindly help me to get pm motor generator ( 200W 12v dc 1000 rpm ) as mentioned 20 + USD. I need only generator part n amteck is very costly.

I need to find a dc motor that can produce AC, for 1kw, 12/240volts at 400rpm up wards. High speed permanent magnetic generator. I would like to find a indian manufacturer if possible. sir please help me for my project.

I want to produce 5 Volt, 1 A current constantly, now which DC motor which RPM am used? And also Which Windmill blade is suitable and size?

Sir which motor should I buy to produce 12volt and also the blade size. I want to build a circular (bicycle wheel) vertical wind turbine. How much blade should I use and size

Hi i am hoping to get power to my weekend retreat.Local electricity company want a lot of money to re connect.Hence looking for advice on a new motor i could purchase at a good price €250 here in Ireland.Hoping to find out will this motor be suitable…any help would be appreciated.

W-DA160LR 15KW

brook crompton

or would it be overkill

In the paragraph above BASIC POWER FORMULA,it is mentioned that “THE LOWER THE RPM SPEED,THE LESS THE OUTPUT POWER”

but in the FAQ’s it is mentioned that

Q: Which is the best DC motor for electricity production?

A: Motors with a lower RPM value and high output voltage might be more efficient.

Q: What are the things that I should take into consideration when I purchase a motor?

A: The standard wind speed is 10–30 Mph, so the motor you will buy should have low RPM values. The blades connected to the motor can produce 400 – 600 RPM speed for a standard wind. For this reason a motor with a maximum 1000 RPM works inefficiently.

I want to build a small windmill for a school project consisting of 12 volt dc motor, i wanna ask that what should be the rpm of the motor if the wind spped is 10 mph

i want to make commercial windmill 250 k.w.or more.but it should be at low cost with good quality.

Is it possible to plug a 5v phone directly to the output of the motor

You must use voltage regulator.

If I want 150_250km/h wind speed what kind of propeller I need? And what motor specifications I need?

I m very curious abt this solar n wind power. And everyone must install wind or solar power on their house top.i m interested first in wind power .and i want to start n install wind power as a exapmle.let u plzz tell me wht capacity of permanant magtic dc motor for starter i sud use plzz guide thnx plzz guide …yatil raut

I hv keen interest in wind power.i want to what are part in wind power exactly.so i could plan …dc motor ..blade and other parts ?

I want to help my grandaughter with a school project wind turbine. We need only to light up a few 3v led globes, what would be the best motor & blade combination? We are only able to use a hair dryer as a wind source.

Dear Sir,

Hope you are fine.

Your artical is v nice for those who wants to make wind turbine project.

My uestion

Dear sir,

I have Ametek 40Volt dc motor , i just wana know how much apms they can produse.

Is it a good dc motor for wind project.

Thank u

Hi there I’m doing a final major project for final year at DMU in UK. I’m redesigning a wind turbine for different purposes. I wanted to work out the best output motors to genorate for 3 different areas. That is 3 different motors.

1 for houses with 80mm radius blades length of 340mm X5 that could work at 25mph wind speed 12V charging a portable battery unit.

2 for low speed vehicles at 40mph and 80mm radious blades length of 340mm X5 charging electric car battries.

3 for high speed 60mph and 80mm radius blades length of 340mm X5 charging electric car batteries.

These have sweet corn shaped turbines that work 360 all around and they work with the wind flow through a tube style tunnel and move the blades in the process.

if i have 12 and 24 v of motor then what kind of weight of rotor i have to take for vertical wind energy???